OUR ITEMS

Lubricants Additive

ITEMS

| Application | Chemistry | |

|---|---|---|

| Package | PCMO , HDDEO , Marine Lubricants , ATF , Gear Oil , Industrial Lubricants etc | |

| Anti Oxidant | Lubricants are likely oxidized due to existance of oxigen in the system. Oxidation cause insoluble sludge in lubricants and then viscosity will increase and damage bearings or piston rings etc… AO would stop this oxdation progress. |

ZnDTP / Hidered amine / Hindered phenol |

| VII (VM) | Lubricants tend to be thick in low temperature and thin in high temperature. Viscosity Index Improver (VII) will minimise this viscosity change. |

OCP(Olefine Co Polymer)/ Styrene Isoprene / PMA (Poly Meta Acrylate ) |

| Friction Modifier | Oil soluble:Adsorb to metal surface to form film and reduce metal surface/surface friction. Non oil soluble (solid) : Form crystal layer and cause friction reduction between layer and layer. |

Graphite / PTFE / BN / MoS2 / Mo-DTC 、Mo-DTP |

| Detergent | Widely used for applications such as automotive , industrial , agricultural machines & marine engines. Especially , disperse sludge generated by high temperature in diesel engine oil and keep engine clean. |

Sulfonate / Phenate / Salicylate |

| Diepersant | Widely used for applications such as automotive , industrial , agricultural machines & marine engines. Prevent growth of mimic / soot in engine oil and disperse . |

PIBSI (Ca、Na、Mg) |

| PPD | Oil as it's nature , precipitate wax when temperature go down lower and lose it's fluidity. PPD will stick to wax surface and prevent growth. |

PMA EVA |

| Anti foam | When lubricants continuously aditated , uptake air into oil and form stable bubble. Bubble prevent lubricants to spread onto friction furface and cause leakage. Anti foamer will make bubble easy to break. |

Butyl poly acrylate |

| Corrosion inhibitor | Provide protection film to metal surface and prevent corrosion. | Di thio carbamate |

| Anti rust | Neutralize acid or form protection film to metal surface in order to prevent oxigen or water to contact. Prevent metal from rusting. |

Oxidized wax / Na Sulfonate |

| Lubricity improver | Form oil film on friction surfice to improve lubricity and reduce friction and wear. | Fatty acid ester / Organic acid Mo |

| Anti wear | Form film on metal surface and prevent direct contact of metal to metal. | ZnDTP / ZnDTC / Carbamine acid / Organic acid Mo |

| Extreme pressure | React faster than Anti wear agent to metal surface and enable to bear heavier load. | Phosphoric acid ester amine salt / Tri polysulfide / Sulfur olefine |

ADDITIVE SUPPLIERS

FUNCTIONAL PRODUCTS

| Tackfier | Typical vis cSt @ 100C |

Recommended dosage(%) | |

|---|---|---|---|

| PARATAC | Can be used for all industrial application such as chain oil , rope oil , oven gear oil etc… | 3,000 | 0.5-2.0 |

| V-176 | Good shear stabirity and threading property. Mix PIB into paraffinic mineral oil. | 3,000 | 0.5-2.0 |

| V-380 | Have a good tackiness @ 200C temperature. | 5,000 | 0.5-2.0 |

| V-422 | Good shear stability and threading property - food grade. Mix PIB into technical white. | 3,000 | 0.5-2.0 |

| V-584 | Tackifier for vegitable oil - food grade. Approved by LuSC / VGP. Excellent thereadng property. | 2,500 @ 40C | 3.0-10.0 |

| V-802 | Polymer for oil in water emulsion - environmently friendly solution. | 40,000 @ 40C | 0.3-5.0 |

| Viscosity improver | Shear stability (PSSI) ASTM D6278 | Adhesive effect 32, cSt @ 100C |

Typical vis cSt @ 100C |

Recommended dosage (%) |

|

|---|---|---|---|---|---|

| V-158F | Mix liquid viscous OCP into oaraffinic base oil. | 45 | 10% = 12.5 | 1,600 | 5.0-10 |

| V-508F | Liquid LuSC / VGP. Approved as viscosity improver for food grade vegitable oil and esters. | 28 | 12% = 45 | 7,000 | 5.0-10 |

| V-515 | Liquid viscosity improver for vegitable oil and esters. | 50 | 10% = 12. | 8,000 | 5.0-10 |

| MH-7000 | Excellent viscosity improving liquid PMA - VII | 36 | 10% = 15 | 1,500 | 5.0-10 |

| MG-3000 | Excellent shear stability liquid PMA (VII) for gear oil. (20〜25wt% dosage / KRL=20) | 0 | 10% = 8.6 | 550 | 10 – 30 |

| Grease additive | Recommended dosage (%) |

|

|---|---|---|

| V-207 | Quick soluble polymer in low temperature oil. Excellent shear stability and washability. | 0.5-2.0 |

| V-4020 | Pellet type polymer. Improve washability at low dosage. | 0.2 –1.0 |

| V-4033 | Liquid polymer (conc). Improve shear stability and washability. | 3.0 – 5.0 |

| Speciality additive & package | Recommended dosage (%) |

|

|---|---|---|

| CI-426 | Corrosion inhibitor and anti wear package for foor grade. | 0.5-2.0 |

| GA-604 | Multi functional industrial oven and closed gear oil package for mineral oil / vegitable oil. | 2.3 |

| RD-535 | Bio base gear oil package . Timken > 70 pounds / Burn load = 250kg. Rock drill , grease , oven gear package. | 2.0 - 7.0 |

| SGP-567 | Bio base oil package including friction modifier , corrosion inhibitor and anti wear agent. | 1.5 |

| MW-612 | Water soluble anti mist additive. | 0.02 - 0.1 |

| WA-60SF | Colorless , low odor , sulfur free sliding surface oil package. Passed Cincinnati Fives stick-slip test. | 1.5 |

| WA-64 | Sliding surface oil package. Colorless , low odor , soluble for various base oils. Passed Cincinnati Fives LS-2 stick-slip test. | 1.75 |

| Pour Point Depressant (PPD) | Recommended dosage (%) |

|

|---|---|---|

| PD-585 | PPD for vegitable oil. | 0.1 – 0.5 |

| PD-590 | Biodegradable PPD. Safety than LuSC eco label or EPA. No carcinogenic substance. | 0.1 – 0.5 |

| PD-555C | PPD for vegitable oil. Effective by -33℃ and suitable for sun flower , soy bean , canola oil and TMPTO ester. | 0.1 – 0.5 |

| PD-610 | PPD for mineral oil. Effective by ‐55℃ in Gp I / II . As for GpIII , PD-630 is suitable. | 0.1 – 0.5 |

Fuel Additive

ITEMS

| Application | Chemistry | |

|---|---|---|

| Detergent | Remove deposit in engine generated by high temperature drive and clean inside the engine. | PIBA(Poly isobutene amine) PEA (Poly ether amine) |

| Anti oxidant | When fuel is oxidized , resin will be produced and impede lubricity.Preventing oxidation would stop generation of resin. Used for gasoline , jet fuel , kerosine and diesel fuel. |

DBPC(2,6-di tertiary butyl-4-methyl phenyl) |

| PPD | In low temperature , wax in fuel is solidified and fluidity will be worse. PPD will prevent solidification of wax and improve liquidity of fuel. |

EVA(Ethylene vinyl acetate) PMA(Poly meta acrylate) |

| Cetane improver | improve firing and burning property of diesel fuel and prevent unexpected noise / vibration of diesel engine. | Nitric acid ester |

| Sludge dispersant | Disperse high molecular matter in fuel in order to prevent plugging and incomplete combustion by sludge, | Alkaline earth metal salts |

| Lubricity improver | Additive to improve lubricity of gasoline and diesel fuel. | Fatty acid ester |

| Biocide | Slime control agent | Thiazoline compounds |

ADDITIVE SUPPLIERS

Synthetic base oils

Exxon Mobil Chemical

| 用途 | |

|---|---|

| Poly Alfa Olefin(PAO) |

PAO is hydro carbon which is same kind of composition as mineral oil. However PAO doesn't contain sulfur as impurity and viscosity property is relatively independent to temperature change. It can be used like mineral oil as base oil with additives and is widely used for high quality engine oil and industrial libricants. ① Keep oil film under high temperature ② Low temperature fluidity is good thus better engine start. ③ Thermal / Oxdation stability is good thus long life. ④ Metal and plastic attack is mild. ⑤ Low volatility property. |

| Ester(Di ester , Polyol ester) |

Viscosity property is independent to temperature change like PAO and used as base oil for engine oil , drivetrain fluid and used as lubricity improver for metal working fluid. It can be used like mineral oil as base oil with additives and is widely used for high quality engine oil and industrial lubricants. ① Good for wide temperature range. ② High flash point thus good volatility property. ③ Excellent thermal / oxidation stability under high temperature. ④ Affinity to metal surface is good thus better lubricity. ⑤ Viscosity property is relatively independent to temperature change. |

| Alkyl Naphthalene | Excellent solubility with additives thus effectiveness of additive is sufficient. Categorized in API - Gp V however thermal / oxidation / hydrolysis stability is better than other Gp Vs and can be used for multiple application as base oil. |

High-viscosity base stock properties

| Test | Method | Units | SpectraSyn™ 40 |

SpectraSyn™ 100 |

SpectraSyn Elite™ 65 |

SpectraSyn Elite™ 150 |

SpectraSyn Elite™ 300 |

|---|---|---|---|---|---|---|---|

| Kinematic viscosity 100 ℃ | ASTM* D445 | cSt | 39 | 100 | 65 | 156 | 303 |

| Kinematic viscosity 40 ℃ | ASTM* D445 | cSt | 396 | 1240 | 614 | 1649 | 3358 |

| Viscosity index | ASTM* D2270 | none | 147 | 170 | 179 | 210 | 241 |

| pour point | ASTM* D5970/D97 |

℃ | -36 | -30 | -42 | -33 | -33 |

| Flash point, COC | ASTM D92 | ℃ | 281 | 283 | 277 | 277 | 286 |

| Brookfield viscosity @-26 ℃ | ASTM* D2983 | cP | 102,000 | 745,000 | 85,400 | 345,000 | 778,333 |

| KRL share, 20hr | CEC L-45-A-99 | %KV100℃ loss | 0.3 | 0.1 | -0.1 | 0.2 | 1.8 |

| KRL share, 100hr | CEC L-45-A-99 | %KV100℃ loss | 0 | 0.5 | 0.3 | 0.3 | -0.4 |

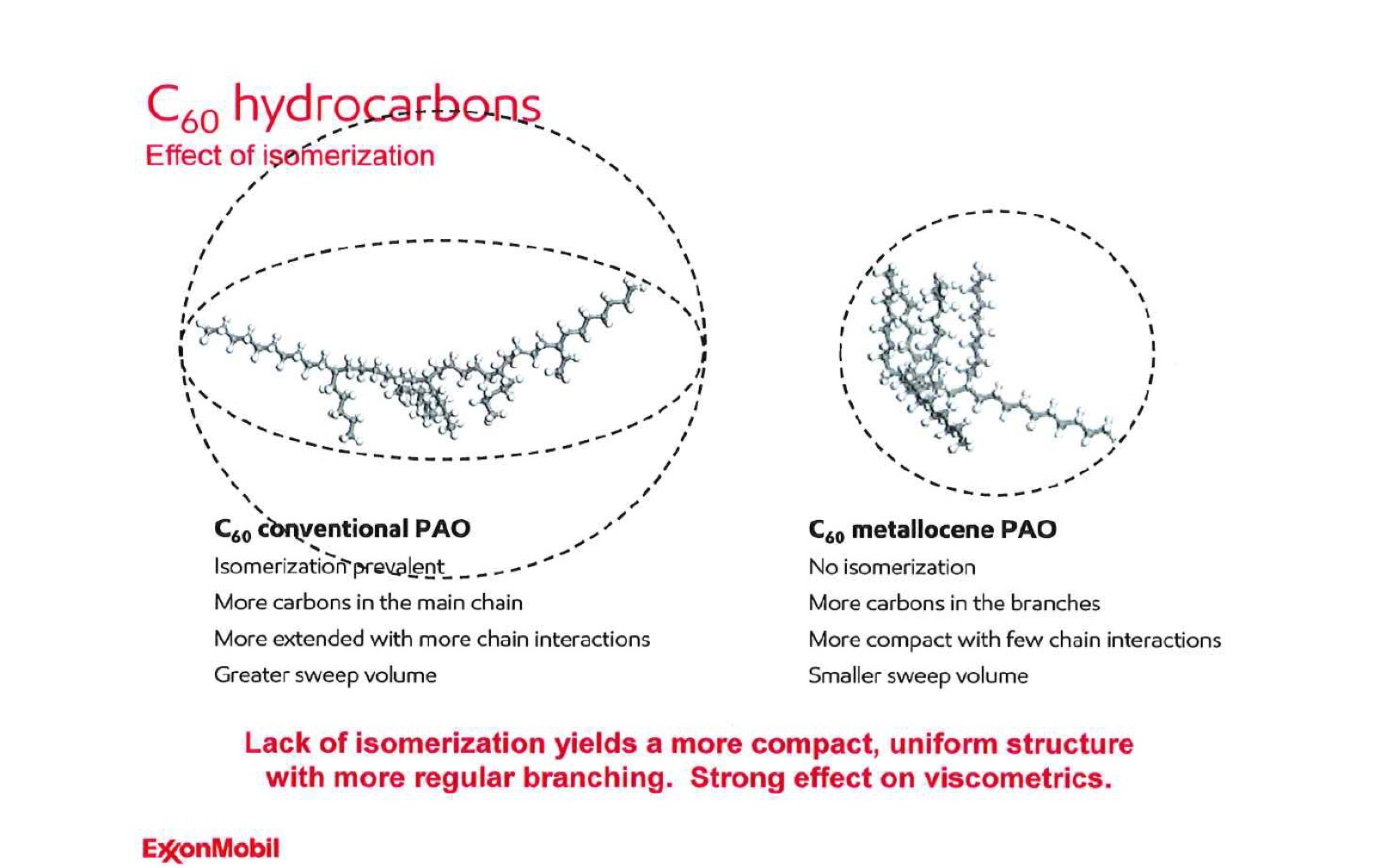

Metallocene technology offers improved performance for high viscosity PAO

Source:ExxonMobil data、single sample determination.Public domain-typical properties.

Metallocene PAO’s structure

Oleon

Oleon makes oleo chemical products derived from natural fats and oils that are essential to your life.

The Oleon products are produced from renewale source and biodegradable / high performance.

Engine oil , Tramsmission , Hydraulic fluid , Gear oil , Compressor oil , Refrigerant oil , Grease etc...

- ・MONO-ALCOHOL ESTERS

- ・METHYL ESTERS

- ・ISOPROPYL ESTERS

- ・n-BUTHYL ESTERS

- ・ISOBUTYL ESTERS

- ・2-ETHYLHEXYL ESTERS

- ・ISOTRIDECYL ESTERS

- ・STEARYL ESTERS

- ・EMULSIFIERS

- ・PROPYLENE GRYCOL ESTERS

- ・POLYETHYLENE GLYCOL ESTERS

- ・SORBITAN ESTERS

- ・GLYCERIDES

- ・POLYOL ESTERS

- ・PROPYLENE GLYCOL ESTERS

- ・GLYCERIDES

- ・NEOPENTYL GLYCOL ESTERS

- ・TRIMETHYLOLPROPANE ESTERS

- ・PENTAERYTHRITOL ESTERS

- ・POLYGLYCEROL ESTERS

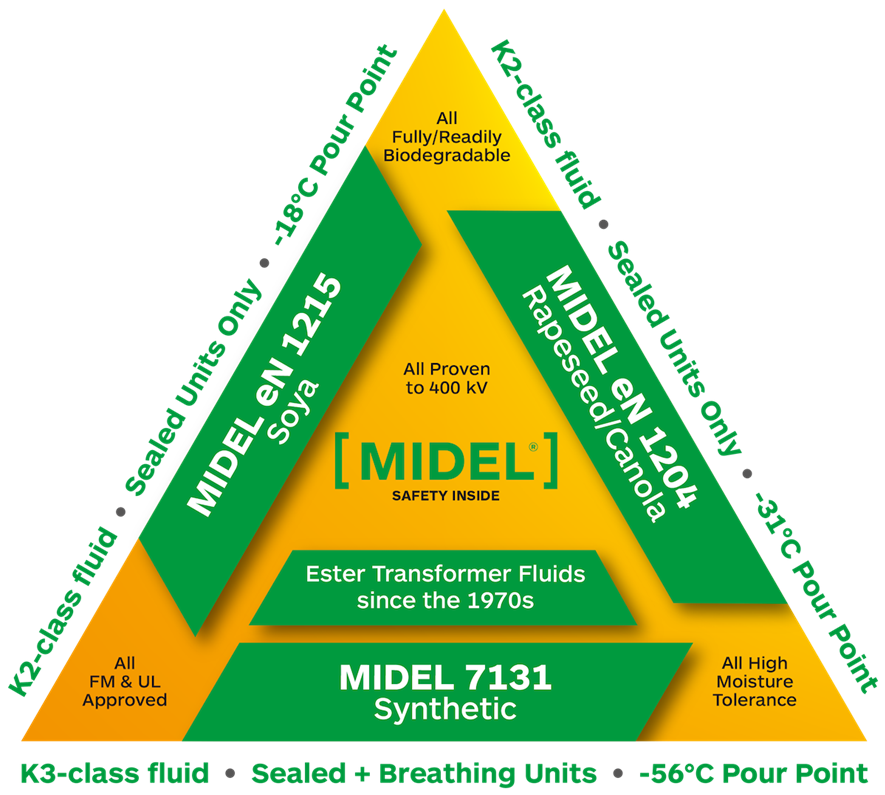

Natural & Synthetic Ester Transformer Fluids

MIDEL is one of the M&I MATERIAL LTD group based in UK.

MIDEL is one of the M&I MATERIAL LTD group based in UK.

Specialized manufacturer of ester type electrical insulating oil since 1970s with a wealth of experience and history.

MIDEL supply insulating oil for EU countries , USA , Middle east & ASEAN countries globally. Electrical insulating oils consist of fire resistant synthetic ester , plant based natural esters ( rape seed & soya bean ) and user can select them by application , characteristic and various conditions.

It’s unique environmental friendliness , high safety for fires , chemical / electrical properties are evaluated and formulated to be used in distribution transformer and power transformer.

MIDEL ester electrical insulating oil is no harm for standard material or parts used for transformer and no effect to fluid controlling devices.

Excellent electric insulation property and chemical stability improve thermal characteristic of insulation oil. This fact is proved by power company and railroad company selected MIDEL world wide.

| Synthetic Ester MIDEL7131 | Rapeseed/Canola Ester MIDEL eN1204 | Soya Ester MIDEL eN1215 | Mineral Oil (Typical) | |

|---|---|---|---|---|

| Flash Point | 260℃ | 315℃ | 315℃ | 142℃ |

| Pour Point | -56℃ | -31℃ | -18℃ | -32℃ |

| Bio degradability | 80~90% | 90~100% | 90~100% | 40~50% |

| Characteristic | Excellent Low temperature property | Excellent Safety | Excellent Safety | Low Cost |

Speciality chemicals

The products - Engine oil / Gear oil / Fuel additive etc... In many ways , Our products can improve / maintain original material's property and performance. Nippon Chemicals Sales Co., Ltd. Our company's strength is technical innovation to develop speciality products with needs from our customers and manage to commercializethe products from selection of raw materials and formulation. Possible - all done by order made and full support.

■Additive package for enine oil and gear oil Performance

- *Reduce wear , friction of metal surface

- *Strengthen oil film thickness

- *Long drain interval for engine oil

- *Prevent degradation of lubricants

- *Improve fuel economy

- *Reduce noise of engine etc..

■Fuel additive Performance

- *Keep clean combustion chamber

- *Removal of carbon deposit

- *Improve fuel efficiency

- *Better accel response

- *Maintain engine performance

- *Clean exhausted gas etc…